LnRiLWZpZWxke21hcmdpbi1ib3R0b206MC43NmVtfS50Yi1maWVsZC0tbGVmdHt0ZXh0LWFsaWduOmxlZnR9LnRiLWZpZWxkLS1jZW50ZXJ7dGV4dC1hbGlnbjpjZW50ZXJ9LnRiLWZpZWxkLS1yaWdodHt0ZXh0LWFsaWduOnJpZ2h0fS50Yi1maWVsZF9fc2t5cGVfcHJldmlld3twYWRkaW5nOjEwcHggMjBweDtib3JkZXItcmFkaXVzOjNweDtjb2xvcjojZmZmO2JhY2tncm91bmQ6IzAwYWZlZTtkaXNwbGF5OmlubGluZS1ibG9ja311bC5nbGlkZV9fc2xpZGVze21hcmdpbjowfQ==

LnRiLWhlYWRpbmcuaGFzLWJhY2tncm91bmR7cGFkZGluZzowfQ==

LnRiLWdyaWQsLnRiLWdyaWQ+LmJsb2NrLWVkaXRvci1pbm5lci1ibG9ja3M+LmJsb2NrLWVkaXRvci1ibG9jay1saXN0X19sYXlvdXR7ZGlzcGxheTpncmlkO2dyaWQtcm93LWdhcDoyNXB4O2dyaWQtY29sdW1uLWdhcDoyNXB4fS50Yi1ncmlkLWl0ZW17YmFja2dyb3VuZDojZDM4YTAzO3BhZGRpbmc6MzBweH0udGItZ3JpZC1jb2x1bW57ZmxleC13cmFwOndyYXB9LnRiLWdyaWQtY29sdW1uPip7d2lkdGg6MTAwJX0udGItZ3JpZC1jb2x1bW4udGItZ3JpZC1hbGlnbi10b3B7d2lkdGg6MTAwJTtkaXNwbGF5OmZsZXg7YWxpZ24tY29udGVudDpmbGV4LXN0YXJ0fS50Yi1ncmlkLWNvbHVtbi50Yi1ncmlkLWFsaWduLWNlbnRlcnt3aWR0aDoxMDAlO2Rpc3BsYXk6ZmxleDthbGlnbi1jb250ZW50OmNlbnRlcn0udGItZ3JpZC1jb2x1bW4udGItZ3JpZC1hbGlnbi1ib3R0b217d2lkdGg6MTAwJTtkaXNwbGF5OmZsZXg7YWxpZ24tY29udGVudDpmbGV4LWVuZH0gLndwLWJsb2NrLXRvb2xzZXQtYmxvY2tzLWdyaWQudGItZ3JpZFtkYXRhLXRvb2xzZXQtYmxvY2tzLWdyaWQ9IjNkYTQ5MjRmMTdiYzdkNDRhZWI5YWI3ZWQ0MjRlYzk2Il0geyBwYWRkaW5nOiAyJSAxNSUgMiUgMTUlO21hcmdpbi1ib3R0b206IC00JTtncmlkLXRlbXBsYXRlLWNvbHVtbnM6IG1pbm1heCgwLCAwLjQyZnIpIG1pbm1heCgwLCAwLjU4ZnIpO2dyaWQtY29sdW1uLWdhcDogNDBweDtncmlkLWF1dG8tZmxvdzogcm93IH0gLndwLWJsb2NrLXRvb2xzZXQtYmxvY2tzLWdyaWQudGItZ3JpZFtkYXRhLXRvb2xzZXQtYmxvY2tzLWdyaWQ9IjNkYTQ5MjRmMTdiYzdkNDRhZWI5YWI3ZWQ0MjRlYzk2Il0gPiAudGItZ3JpZC1jb2x1bW46bnRoLW9mLXR5cGUoMm4gKyAxKSB7IGdyaWQtY29sdW1uOiAxIH0gLndwLWJsb2NrLXRvb2xzZXQtYmxvY2tzLWdyaWQudGItZ3JpZFtkYXRhLXRvb2xzZXQtYmxvY2tzLWdyaWQ9IjNkYTQ5MjRmMTdiYzdkNDRhZWI5YWI3ZWQ0MjRlYzk2Il0gPiAudGItZ3JpZC1jb2x1bW46bnRoLW9mLXR5cGUoMm4gKyAyKSB7IGdyaWQtY29sdW1uOiAyIH0gLndwLWJsb2NrLXRvb2xzZXQtYmxvY2tzLWdyaWQtY29sdW1uLnRiLWdyaWQtY29sdW1uW2RhdGEtdG9vbHNldC1ibG9ja3MtZ3JpZC1jb2x1bW49IjQ1NTBjNTk0ZDI1NjE5ZDY3Mzg2YWVmZjRjNmFiNTk1Il0geyBkaXNwbGF5OiBmbGV4OyB9IC50Yi1idXR0b257Y29sb3I6I2YxZjFmMX0udGItYnV0dG9uLS1sZWZ0e3RleHQtYWxpZ246bGVmdH0udGItYnV0dG9uLS1jZW50ZXJ7dGV4dC1hbGlnbjpjZW50ZXJ9LnRiLWJ1dHRvbi0tcmlnaHR7dGV4dC1hbGlnbjpyaWdodH0udGItYnV0dG9uX19saW5re2NvbG9yOmluaGVyaXQ7Y3Vyc29yOnBvaW50ZXI7ZGlzcGxheTppbmxpbmUtYmxvY2s7bGluZS1oZWlnaHQ6MTAwJTt0ZXh0LWRlY29yYXRpb246bm9uZSAhaW1wb3J0YW50O3RleHQtYWxpZ246Y2VudGVyO3RyYW5zaXRpb246YWxsIDAuM3MgZWFzZX0udGItYnV0dG9uX19saW5rOmhvdmVyLC50Yi1idXR0b25fX2xpbms6Zm9jdXMsLnRiLWJ1dHRvbl9fbGluazp2aXNpdGVke2NvbG9yOmluaGVyaXR9LnRiLWJ1dHRvbl9fbGluazpob3ZlciAudGItYnV0dG9uX19jb250ZW50LC50Yi1idXR0b25fX2xpbms6Zm9jdXMgLnRiLWJ1dHRvbl9fY29udGVudCwudGItYnV0dG9uX19saW5rOnZpc2l0ZWQgLnRiLWJ1dHRvbl9fY29udGVudHtmb250LWZhbWlseTppbmhlcml0O2ZvbnQtc3R5bGU6aW5oZXJpdDtmb250LXdlaWdodDppbmhlcml0O2xldHRlci1zcGFjaW5nOmluaGVyaXQ7dGV4dC1kZWNvcmF0aW9uOmluaGVyaXQ7dGV4dC1zaGFkb3c6aW5oZXJpdDt0ZXh0LXRyYW5zZm9ybTppbmhlcml0fS50Yi1idXR0b25fX2NvbnRlbnR7dmVydGljYWwtYWxpZ246bWlkZGxlO3RyYW5zaXRpb246YWxsIDAuM3MgZWFzZX0udGItYnV0dG9uX19pY29ue3RyYW5zaXRpb246YWxsIDAuM3MgZWFzZTtkaXNwbGF5OmlubGluZS1ibG9jazt2ZXJ0aWNhbC1hbGlnbjptaWRkbGU7Zm9udC1zdHlsZTpub3JtYWwgIWltcG9ydGFudH0udGItYnV0dG9uX19pY29uOjpiZWZvcmV7Y29udGVudDphdHRyKGRhdGEtZm9udC1jb2RlKTtmb250LXdlaWdodDpub3JtYWwgIWltcG9ydGFudH0udGItYnV0dG9uX19saW5re2JhY2tncm91bmQtY29sb3I6IzQ0NDtib3JkZXItcmFkaXVzOjAuM2VtO2ZvbnQtc2l6ZToxLjNlbTttYXJnaW4tYm90dG9tOjAuNzZlbTtwYWRkaW5nOjAuNTVlbSAxLjVlbSAwLjU1ZW19IC50Yi1idXR0b25bZGF0YS10b29sc2V0LWJsb2Nrcy1idXR0b249ImM5NzczYjM4ZGQ0NWYzMzU3MzE1ZjRkNTZlZmYwMjAyIl0gLnRiLWJ1dHRvbl9fbGluayB7IGJhY2tncm91bmQtY29sb3I6IHJnYmEoIDIyNywgNiwgMTksIDEgKTsgfSAudGItYnV0dG9uW2RhdGEtdG9vbHNldC1ibG9ja3MtYnV0dG9uPSJjOTc3M2IzOGRkNDVmMzM1NzMxNWY0ZDU2ZWZmMDIwMiJdIC50Yi1idXR0b25fX2ljb24geyBmb250LWZhbWlseTogZGFzaGljb25zOyB9ICBoMi50Yi1oZWFkaW5nW2RhdGEtdG9vbHNldC1ibG9ja3MtaGVhZGluZz0iNmY4MzVjZDQyZTQzZjkxOGRlZTA1ZTkwOTUxYzg3YWMiXSAgeyBwYWRkaW5nLXRvcDogMyU7bWFyZ2luLWJvdHRvbTogLTMlOyB9ICAud3AtYmxvY2stdG9vbHNldC1ibG9ja3MtZ3JpZC1jb2x1bW4udGItZ3JpZC1jb2x1bW5bZGF0YS10b29sc2V0LWJsb2Nrcy1ncmlkLWNvbHVtbj0iYjYzMDBlNGE4ZTBmYTMwOTdiYTBhYzE5MDJhYWUxODYiXSB7IGRpc3BsYXk6IGZsZXg7IH0gLnRiLWltYWdlLXNsaWRlci0tY2Fyb3VzZWx7b3BhY2l0eTowO2RpcmVjdGlvbjpsdHJ9LnRiLWltYWdlLXNsaWRlciAuZ2xpZGV7cG9zaXRpb246cmVsYXRpdmV9LnRiLWltYWdlLXNsaWRlciAuZ2xpZGVfX3NsaWRle2hlaWdodDphdXRvO3Bvc2l0aW9uOnJlbGF0aXZlO21hcmdpbi1sZWZ0OjB9LnRiLWltYWdlLXNsaWRlciAuZ2xpZGVfX3NsaWRlLS1jbG9uZXtjdXJzb3I6cG9pbnRlcn0udGItaW1hZ2Utc2xpZGVyIC5nbGlkZV9fc2xpZGUgaW1ne3dpZHRoOjEwMCU7ZmxvYXQ6bm9uZSAhaW1wb3J0YW50fS50Yi1pbWFnZS1zbGlkZXIgLmdsaWRlX192aWV3e3dpZHRoOjEwMCU7dHJhbnNpdGlvbjpvcGFjaXR5IDM1MG1zIGVhc2UtaW4tb3V0O3Bvc2l0aW9uOnJlbGF0aXZlfS50Yi1pbWFnZS1zbGlkZXIgLmdsaWRlX192aWV3IGltZ3stby1vYmplY3QtZml0OmNvbnRhaW47b2JqZWN0LWZpdDpjb250YWluO3dpZHRoOjEwMCU7ZmxvYXQ6bm9uZSAhaW1wb3J0YW50fS50Yi1pbWFnZS1zbGlkZXIgLmdsaWRlX192aWV3LS1mYWRlLW91dHtvcGFjaXR5OjB9LnRiLWltYWdlLXNsaWRlciAuZ2xpZGVfX3ZpZXctLWZhZGUtaW57b3BhY2l0eToxfS50Yi1pbWFnZS1zbGlkZXIgLmdsaWRlX19hcnJvd3tib3JkZXI6bm9uZTtwb3NpdGlvbjphYnNvbHV0ZTt6LWluZGV4OjEwO3RvcDo1MCU7ZGlzcGxheTppbmxpbmUtZmxleDtqdXN0aWZ5LWNvbnRlbnQ6Y2VudGVyO2FsaWduLWl0ZW1zOmNlbnRlcjt3aWR0aDo0MHB4O2hlaWdodDo0MHB4O3RleHQtYWxpZ246Y2VudGVyO3BhZGRpbmc6MDtjdXJzb3I6cG9pbnRlcjt0cmFuc2Zvcm06dHJhbnNsYXRlWSgtNTAlKTtib3JkZXItcmFkaXVzOjUwcHg7dHJhbnNpdGlvbjphbGwgMC4ycyBsaW5lYXI7YmFja2dyb3VuZDpyZ2JhKDI1NSwyNTUsMjU1LDAuNyl9LnRiLWltYWdlLXNsaWRlciAuZ2xpZGVfX2Fycm93OmZvY3Vze291dGxpbmU6bm9uZTtib3gtc2hhZG93OjAgMCA1cHggIzY2NjtiYWNrZ3JvdW5kOnJnYmEoMjU1LDI1NSwyNTUsMC43KTtvcGFjaXR5OjF9LnRiLWltYWdlLXNsaWRlciAuZ2xpZGVfX2Fycm93OmhvdmVye2JhY2tncm91bmQ6cmdiYSgyNTUsMjU1LDI1NSwwLjkpfS50Yi1pbWFnZS1zbGlkZXIgLmdsaWRlX19hcnJvdy0tbGVmdHtsZWZ0OjVweH0udGItaW1hZ2Utc2xpZGVyIC5nbGlkZV9fYXJyb3ctLWxlZnQgc3Zne21hcmdpbi1sZWZ0Oi0xcHh9LnRiLWltYWdlLXNsaWRlciAuZ2xpZGVfX2Fycm93LS1sZWZ0IHNwYW4udGItc2xpZGVyLWxlZnQtYXJyb3d7ZGlzcGxheTppbmxpbmUtYmxvY2s7d2lkdGg6MjVweDtoZWlnaHQ6MjVweDtiYWNrZ3JvdW5kLWltYWdlOnVybCgiZGF0YTppbWFnZS9zdmcreG1sLCUzQ3N2ZyB4bWxucz0naHR0cDovL3d3dy53My5vcmcvMjAwMC9zdmcnIHZpZXdCb3g9JzAgMCAxMjkgMTI5JyB3aWR0aD0nMjUnIGhlaWdodD0nMjUnJTNFJTNDZyUzRSUzQ3BhdGggZD0nbTcwLDkzLjVjMC44LDAuOCAxLjgsMS4yIDIuOSwxLjIgMSwwIDIuMS0wLjQgMi45LTEuMiAxLjYtMS42IDEuNi00LjIgMC01LjhsLTIzLjUtMjMuNSAyMy41LTIzLjVjMS42LTEuNiAxLjYtNC4yIDAtNS44cy00LjItMS42LTUuOCwwbC0yNi40LDI2LjRjLTAuOCwwLjgtMS4yLDEuOC0xLjIsMi45czAuNCwyLjEgMS4yLDIuOWwyNi40LDI2LjR6JyBmaWxsPSclMjM2NjYnLyUzRSUzQy9nJTNFJTNDL3N2ZyUzRSIpfS50Yi1pbWFnZS1zbGlkZXIgLmdsaWRlX19hcnJvdy0tcmlnaHR7cmlnaHQ6NXB4fS50Yi1pbWFnZS1zbGlkZXIgLmdsaWRlX19hcnJvdy0tcmlnaHQgc3Zne21hcmdpbi1yaWdodDotMXB4fS50Yi1pbWFnZS1zbGlkZXIgLmdsaWRlX19hcnJvdy0tcmlnaHQgc3Bhbi50Yi1zbGlkZXItcmlnaHQtYXJyb3d7ZGlzcGxheTppbmxpbmUtYmxvY2s7d2lkdGg6MjVweDtoZWlnaHQ6MjVweDtiYWNrZ3JvdW5kLWltYWdlOnVybCgiZGF0YTppbWFnZS9zdmcreG1sLCUzQ3N2ZyB4bWxucz0naHR0cDovL3d3dy53My5vcmcvMjAwMC9zdmcnIHZpZXdCb3g9JzAgMCAxMjkgMTI5JyB3aWR0aD0nMjUnIGhlaWdodD0nMjUnJTNFJTNDZyUzRSUzQ3BhdGggZD0nbTUxLjEsOTMuNWMwLjgsMC44IDEuOCwxLjIgMi45LDEuMiAxLDAgMi4xLTAuNCAyLjktMS4ybDI2LjQtMjYuNGMwLjgtMC44IDEuMi0xLjggMS4yLTIuOSAwLTEuMS0wLjQtMi4xLTEuMi0yLjlsLTI2LjQtMjYuNGMtMS42LTEuNi00LjItMS42LTUuOCwwLTEuNiwxLjYtMS42LDQuMiAwLDUuOGwyMy41LDIzLjUtMjMuNSwyMy41Yy0xLjYsMS42LTEuNiw0LjIgMCw1Ljh6JyBmaWxsPSclMjM2NjYnLyUzRSUzQy9nJTNFJTNDL3N2ZyUzRSIpfS50Yi1pbWFnZS1zbGlkZXIgLmdsaWRlOmhvdmVyIC5nbGlkZV9fYXJyb3csLnRiLWltYWdlLXNsaWRlciAuZ2xpZGU6Zm9jdXMgLmdsaWRlX19hcnJvd3tvcGFjaXR5OjF9LnRiLWltYWdlLXNsaWRlci0tY3JvcCAuZ2xpZGVfX3NsaWRlIGltZ3stby1vYmplY3QtZml0OmNvdmVyO29iamVjdC1maXQ6Y292ZXI7aGVpZ2h0OjEwMCUgIWltcG9ydGFudH0udGItaW1hZ2Utc2xpZGVyIC5nbGlkZV9fc2xpZGVze2xpc3Qtc3R5bGUtdHlwZTpub25lO3BhZGRpbmctbGVmdDowO21hcmdpbi1sZWZ0OmF1dG99LnRiLWltYWdlLXNsaWRlcl9fY2FwdGlvbntwb3NpdGlvbjphYnNvbHV0ZTtib3R0b206MDt3aWR0aDoxMDAlO2JhY2tncm91bmQ6cmdiYSgyNTUsMjU1LDI1NSwwLjYpO3RleHQtYWxpZ246Y2VudGVyO2NvbG9yOiMzMzN9LnRiLWltYWdlLXNsaWRlcl9fY2FwdGlvbiA6ZW1wdHl7YmFja2dyb3VuZDp0cmFuc3BhcmVudCAhaW1wb3J0YW50O21hcmdpbjowO3BhZGRpbmc6MH0udGItaW1hZ2Utc2xpZGVyX19jYXB0aW9uIGZpZ2NhcHRpb257cGFkZGluZzo1cHggMnB4O21hcmdpbi10b3A6NXB4fSAudGItaW1hZ2Utc2xpZGVyW2RhdGEtdG9vbHNldC1ibG9ja3MtaW1hZ2Utc2xpZGVyPSI2NTEwNDBhOGQwNzdiOGI0ODZhM2FlYWRhYmY2NGMxZCJdIC50Yi1pbWFnZS1zbGlkZXJfX2NhcHRpb24geyBiYWNrZ3JvdW5kLWltYWdlOmxpbmVhci1ncmFkaWVudCggcmdiYSggMCwgMCwgMCwgMSApLHJnYmEoIDI1NSwgMjU1LCAyNTUsIDEgKSApOyB9IEBtZWRpYSBvbmx5IHNjcmVlbiBhbmQgKG1heC13aWR0aDogNzgxcHgpIHsgLnRiLWdyaWQsLnRiLWdyaWQ+LmJsb2NrLWVkaXRvci1pbm5lci1ibG9ja3M+LmJsb2NrLWVkaXRvci1ibG9jay1saXN0X19sYXlvdXR7ZGlzcGxheTpncmlkO2dyaWQtcm93LWdhcDoyNXB4O2dyaWQtY29sdW1uLWdhcDoyNXB4fS50Yi1ncmlkLWl0ZW17YmFja2dyb3VuZDojZDM4YTAzO3BhZGRpbmc6MzBweH0udGItZ3JpZC1jb2x1bW57ZmxleC13cmFwOndyYXB9LnRiLWdyaWQtY29sdW1uPip7d2lkdGg6MTAwJX0udGItZ3JpZC1jb2x1bW4udGItZ3JpZC1hbGlnbi10b3B7d2lkdGg6MTAwJTtkaXNwbGF5OmZsZXg7YWxpZ24tY29udGVudDpmbGV4LXN0YXJ0fS50Yi1ncmlkLWNvbHVtbi50Yi1ncmlkLWFsaWduLWNlbnRlcnt3aWR0aDoxMDAlO2Rpc3BsYXk6ZmxleDthbGlnbi1jb250ZW50OmNlbnRlcn0udGItZ3JpZC1jb2x1bW4udGItZ3JpZC1hbGlnbi1ib3R0b217d2lkdGg6MTAwJTtkaXNwbGF5OmZsZXg7YWxpZ24tY29udGVudDpmbGV4LWVuZH0gLndwLWJsb2NrLXRvb2xzZXQtYmxvY2tzLWdyaWQudGItZ3JpZFtkYXRhLXRvb2xzZXQtYmxvY2tzLWdyaWQ9IjNkYTQ5MjRmMTdiYzdkNDRhZWI5YWI3ZWQ0MjRlYzk2Il0geyBwYWRkaW5nLXJpZ2h0OiA1JTtwYWRkaW5nLWxlZnQ6IDUlO2dyaWQtdGVtcGxhdGUtY29sdW1uczogbWlubWF4KDAsIDAuNWZyKSBtaW5tYXgoMCwgMC41ZnIpO2dyaWQtYXV0by1mbG93OiByb3cgfSAud3AtYmxvY2stdG9vbHNldC1ibG9ja3MtZ3JpZC50Yi1ncmlkW2RhdGEtdG9vbHNldC1ibG9ja3MtZ3JpZD0iM2RhNDkyNGYxN2JjN2Q0NGFlYjlhYjdlZDQyNGVjOTYiXSA+IC50Yi1ncmlkLWNvbHVtbjpudGgtb2YtdHlwZSgybiArIDEpIHsgZ3JpZC1jb2x1bW46IDEgfSAud3AtYmxvY2stdG9vbHNldC1ibG9ja3MtZ3JpZC50Yi1ncmlkW2RhdGEtdG9vbHNldC1ibG9ja3MtZ3JpZD0iM2RhNDkyNGYxN2JjN2Q0NGFlYjlhYjdlZDQyNGVjOTYiXSA+IC50Yi1ncmlkLWNvbHVtbjpudGgtb2YtdHlwZSgybiArIDIpIHsgZ3JpZC1jb2x1bW46IDIgfSAud3AtYmxvY2stdG9vbHNldC1ibG9ja3MtZ3JpZC1jb2x1bW4udGItZ3JpZC1jb2x1bW5bZGF0YS10b29sc2V0LWJsb2Nrcy1ncmlkLWNvbHVtbj0iNDU1MGM1OTRkMjU2MTlkNjczODZhZWZmNGM2YWI1OTUiXSB7IGRpc3BsYXk6IGZsZXg7IH0gLnRiLWJ1dHRvbntjb2xvcjojZjFmMWYxfS50Yi1idXR0b24tLWxlZnR7dGV4dC1hbGlnbjpsZWZ0fS50Yi1idXR0b24tLWNlbnRlcnt0ZXh0LWFsaWduOmNlbnRlcn0udGItYnV0dG9uLS1yaWdodHt0ZXh0LWFsaWduOnJpZ2h0fS50Yi1idXR0b25fX2xpbmt7Y29sb3I6aW5oZXJpdDtjdXJzb3I6cG9pbnRlcjtkaXNwbGF5OmlubGluZS1ibG9jaztsaW5lLWhlaWdodDoxMDAlO3RleHQtZGVjb3JhdGlvbjpub25lICFpbXBvcnRhbnQ7dGV4dC1hbGlnbjpjZW50ZXI7dHJhbnNpdGlvbjphbGwgMC4zcyBlYXNlfS50Yi1idXR0b25fX2xpbms6aG92ZXIsLnRiLWJ1dHRvbl9fbGluazpmb2N1cywudGItYnV0dG9uX19saW5rOnZpc2l0ZWR7Y29sb3I6aW5oZXJpdH0udGItYnV0dG9uX19saW5rOmhvdmVyIC50Yi1idXR0b25fX2NvbnRlbnQsLnRiLWJ1dHRvbl9fbGluazpmb2N1cyAudGItYnV0dG9uX19jb250ZW50LC50Yi1idXR0b25fX2xpbms6dmlzaXRlZCAudGItYnV0dG9uX19jb250ZW50e2ZvbnQtZmFtaWx5OmluaGVyaXQ7Zm9udC1zdHlsZTppbmhlcml0O2ZvbnQtd2VpZ2h0OmluaGVyaXQ7bGV0dGVyLXNwYWNpbmc6aW5oZXJpdDt0ZXh0LWRlY29yYXRpb246aW5oZXJpdDt0ZXh0LXNoYWRvdzppbmhlcml0O3RleHQtdHJhbnNmb3JtOmluaGVyaXR9LnRiLWJ1dHRvbl9fY29udGVudHt2ZXJ0aWNhbC1hbGlnbjptaWRkbGU7dHJhbnNpdGlvbjphbGwgMC4zcyBlYXNlfS50Yi1idXR0b25fX2ljb257dHJhbnNpdGlvbjphbGwgMC4zcyBlYXNlO2Rpc3BsYXk6aW5saW5lLWJsb2NrO3ZlcnRpY2FsLWFsaWduOm1pZGRsZTtmb250LXN0eWxlOm5vcm1hbCAhaW1wb3J0YW50fS50Yi1idXR0b25fX2ljb246OmJlZm9yZXtjb250ZW50OmF0dHIoZGF0YS1mb250LWNvZGUpO2ZvbnQtd2VpZ2h0Om5vcm1hbCAhaW1wb3J0YW50fS50Yi1idXR0b25fX2xpbmt7YmFja2dyb3VuZC1jb2xvcjojNDQ0O2JvcmRlci1yYWRpdXM6MC4zZW07Zm9udC1zaXplOjEuM2VtO21hcmdpbi1ib3R0b206MC43NmVtO3BhZGRpbmc6MC41NWVtIDEuNWVtIDAuNTVlbX0gaDIudGItaGVhZGluZ1tkYXRhLXRvb2xzZXQtYmxvY2tzLWhlYWRpbmc9IjZmODM1Y2Q0MmU0M2Y5MThkZWUwNWU5MDk1MWM4N2FjIl0gIHsgbWFyZ2luLWJvdHRvbTogLTYlOyB9ICAud3AtYmxvY2stdG9vbHNldC1ibG9ja3MtZ3JpZC1jb2x1bW4udGItZ3JpZC1jb2x1bW5bZGF0YS10b29sc2V0LWJsb2Nrcy1ncmlkLWNvbHVtbj0iYjYzMDBlNGE4ZTBmYTMwOTdiYTBhYzE5MDJhYWUxODYiXSB7IGRpc3BsYXk6IGZsZXg7IH0gLnRiLWltYWdlLXNsaWRlci0tY2Fyb3VzZWx7b3BhY2l0eTowO2RpcmVjdGlvbjpsdHJ9LnRiLWltYWdlLXNsaWRlciAuZ2xpZGV7cG9zaXRpb246cmVsYXRpdmV9LnRiLWltYWdlLXNsaWRlciAuZ2xpZGVfX3NsaWRle2hlaWdodDphdXRvO3Bvc2l0aW9uOnJlbGF0aXZlO21hcmdpbi1sZWZ0OjB9LnRiLWltYWdlLXNsaWRlciAuZ2xpZGVfX3NsaWRlLS1jbG9uZXtjdXJzb3I6cG9pbnRlcn0udGItaW1hZ2Utc2xpZGVyIC5nbGlkZV9fc2xpZGUgaW1ne3dpZHRoOjEwMCU7ZmxvYXQ6bm9uZSAhaW1wb3J0YW50fS50Yi1pbWFnZS1zbGlkZXIgLmdsaWRlX192aWV3e3dpZHRoOjEwMCU7dHJhbnNpdGlvbjpvcGFjaXR5IDM1MG1zIGVhc2UtaW4tb3V0O3Bvc2l0aW9uOnJlbGF0aXZlfS50Yi1pbWFnZS1zbGlkZXIgLmdsaWRlX192aWV3IGltZ3stby1vYmplY3QtZml0OmNvbnRhaW47b2JqZWN0LWZpdDpjb250YWluO3dpZHRoOjEwMCU7ZmxvYXQ6bm9uZSAhaW1wb3J0YW50fS50Yi1pbWFnZS1zbGlkZXIgLmdsaWRlX192aWV3LS1mYWRlLW91dHtvcGFjaXR5OjB9LnRiLWltYWdlLXNsaWRlciAuZ2xpZGVfX3ZpZXctLWZhZGUtaW57b3BhY2l0eToxfS50Yi1pbWFnZS1zbGlkZXIgLmdsaWRlX19hcnJvd3tib3JkZXI6bm9uZTtwb3NpdGlvbjphYnNvbHV0ZTt6LWluZGV4OjEwO3RvcDo1MCU7ZGlzcGxheTppbmxpbmUtZmxleDtqdXN0aWZ5LWNvbnRlbnQ6Y2VudGVyO2FsaWduLWl0ZW1zOmNlbnRlcjt3aWR0aDo0MHB4O2hlaWdodDo0MHB4O3RleHQtYWxpZ246Y2VudGVyO3BhZGRpbmc6MDtjdXJzb3I6cG9pbnRlcjt0cmFuc2Zvcm06dHJhbnNsYXRlWSgtNTAlKTtib3JkZXItcmFkaXVzOjUwcHg7dHJhbnNpdGlvbjphbGwgMC4ycyBsaW5lYXI7YmFja2dyb3VuZDpyZ2JhKDI1NSwyNTUsMjU1LDAuNyl9LnRiLWltYWdlLXNsaWRlciAuZ2xpZGVfX2Fycm93OmZvY3Vze291dGxpbmU6bm9uZTtib3gtc2hhZG93OjAgMCA1cHggIzY2NjtiYWNrZ3JvdW5kOnJnYmEoMjU1LDI1NSwyNTUsMC43KTtvcGFjaXR5OjF9LnRiLWltYWdlLXNsaWRlciAuZ2xpZGVfX2Fycm93OmhvdmVye2JhY2tncm91bmQ6cmdiYSgyNTUsMjU1LDI1NSwwLjkpfS50Yi1pbWFnZS1zbGlkZXIgLmdsaWRlX19hcnJvdy0tbGVmdHtsZWZ0OjVweH0udGItaW1hZ2Utc2xpZGVyIC5nbGlkZV9fYXJyb3ctLWxlZnQgc3Zne21hcmdpbi1sZWZ0Oi0xcHh9LnRiLWltYWdlLXNsaWRlciAuZ2xpZGVfX2Fycm93LS1sZWZ0IHNwYW4udGItc2xpZGVyLWxlZnQtYXJyb3d7ZGlzcGxheTppbmxpbmUtYmxvY2s7d2lkdGg6MjVweDtoZWlnaHQ6MjVweDtiYWNrZ3JvdW5kLWltYWdlOnVybCgiZGF0YTppbWFnZS9zdmcreG1sLCUzQ3N2ZyB4bWxucz0naHR0cDovL3d3dy53My5vcmcvMjAwMC9zdmcnIHZpZXdCb3g9JzAgMCAxMjkgMTI5JyB3aWR0aD0nMjUnIGhlaWdodD0nMjUnJTNFJTNDZyUzRSUzQ3BhdGggZD0nbTcwLDkzLjVjMC44LDAuOCAxLjgsMS4yIDIuOSwxLjIgMSwwIDIuMS0wLjQgMi45LTEuMiAxLjYtMS42IDEuNi00LjIgMC01LjhsLTIzLjUtMjMuNSAyMy41LTIzLjVjMS42LTEuNiAxLjYtNC4yIDAtNS44cy00LjItMS42LTUuOCwwbC0yNi40LDI2LjRjLTAuOCwwLjgtMS4yLDEuOC0xLjIsMi45czAuNCwyLjEgMS4yLDIuOWwyNi40LDI2LjR6JyBmaWxsPSclMjM2NjYnLyUzRSUzQy9nJTNFJTNDL3N2ZyUzRSIpfS50Yi1pbWFnZS1zbGlkZXIgLmdsaWRlX19hcnJvdy0tcmlnaHR7cmlnaHQ6NXB4fS50Yi1pbWFnZS1zbGlkZXIgLmdsaWRlX19hcnJvdy0tcmlnaHQgc3Zne21hcmdpbi1yaWdodDotMXB4fS50Yi1pbWFnZS1zbGlkZXIgLmdsaWRlX19hcnJvdy0tcmlnaHQgc3Bhbi50Yi1zbGlkZXItcmlnaHQtYXJyb3d7ZGlzcGxheTppbmxpbmUtYmxvY2s7d2lkdGg6MjVweDtoZWlnaHQ6MjVweDtiYWNrZ3JvdW5kLWltYWdlOnVybCgiZGF0YTppbWFnZS9zdmcreG1sLCUzQ3N2ZyB4bWxucz0naHR0cDovL3d3dy53My5vcmcvMjAwMC9zdmcnIHZpZXdCb3g9JzAgMCAxMjkgMTI5JyB3aWR0aD0nMjUnIGhlaWdodD0nMjUnJTNFJTNDZyUzRSUzQ3BhdGggZD0nbTUxLjEsOTMuNWMwLjgsMC44IDEuOCwxLjIgMi45LDEuMiAxLDAgMi4xLTAuNCAyLjktMS4ybDI2LjQtMjYuNGMwLjgtMC44IDEuMi0xLjggMS4yLTIuOSAwLTEuMS0wLjQtMi4xLTEuMi0yLjlsLTI2LjQtMjYuNGMtMS42LTEuNi00LjItMS42LTUuOCwwLTEuNiwxLjYtMS42LDQuMiAwLDUuOGwyMy41LDIzLjUtMjMuNSwyMy41Yy0xLjYsMS42LTEuNiw0LjIgMCw1Ljh6JyBmaWxsPSclMjM2NjYnLyUzRSUzQy9nJTNFJTNDL3N2ZyUzRSIpfS50Yi1pbWFnZS1zbGlkZXIgLmdsaWRlOmhvdmVyIC5nbGlkZV9fYXJyb3csLnRiLWltYWdlLXNsaWRlciAuZ2xpZGU6Zm9jdXMgLmdsaWRlX19hcnJvd3tvcGFjaXR5OjF9LnRiLWltYWdlLXNsaWRlci0tY3JvcCAuZ2xpZGVfX3NsaWRlIGltZ3stby1vYmplY3QtZml0OmNvdmVyO29iamVjdC1maXQ6Y292ZXI7aGVpZ2h0OjEwMCUgIWltcG9ydGFudH0udGItaW1hZ2Utc2xpZGVyIC5nbGlkZV9fc2xpZGVze2xpc3Qtc3R5bGUtdHlwZTpub25lO3BhZGRpbmctbGVmdDowO21hcmdpbi1sZWZ0OmF1dG99LnRiLWltYWdlLXNsaWRlcl9fY2FwdGlvbntwb3NpdGlvbjphYnNvbHV0ZTtib3R0b206MDt3aWR0aDoxMDAlO2JhY2tncm91bmQ6cmdiYSgyNTUsMjU1LDI1NSwwLjYpO3RleHQtYWxpZ246Y2VudGVyO2NvbG9yOiMzMzN9LnRiLWltYWdlLXNsaWRlcl9fY2FwdGlvbiA6ZW1wdHl7YmFja2dyb3VuZDp0cmFuc3BhcmVudCAhaW1wb3J0YW50O21hcmdpbjowO3BhZGRpbmc6MH0udGItaW1hZ2Utc2xpZGVyX19jYXB0aW9uIGZpZ2NhcHRpb257cGFkZGluZzo1cHggMnB4O21hcmdpbi10b3A6NXB4fSB9IEBtZWRpYSBvbmx5IHNjcmVlbiBhbmQgKG1heC13aWR0aDogNTk5cHgpIHsgLnRiLWdyaWQsLnRiLWdyaWQ+LmJsb2NrLWVkaXRvci1pbm5lci1ibG9ja3M+LmJsb2NrLWVkaXRvci1ibG9jay1saXN0X19sYXlvdXR7ZGlzcGxheTpncmlkO2dyaWQtcm93LWdhcDoyNXB4O2dyaWQtY29sdW1uLWdhcDoyNXB4fS50Yi1ncmlkLWl0ZW17YmFja2dyb3VuZDojZDM4YTAzO3BhZGRpbmc6MzBweH0udGItZ3JpZC1jb2x1bW57ZmxleC13cmFwOndyYXB9LnRiLWdyaWQtY29sdW1uPip7d2lkdGg6MTAwJX0udGItZ3JpZC1jb2x1bW4udGItZ3JpZC1hbGlnbi10b3B7d2lkdGg6MTAwJTtkaXNwbGF5OmZsZXg7YWxpZ24tY29udGVudDpmbGV4LXN0YXJ0fS50Yi1ncmlkLWNvbHVtbi50Yi1ncmlkLWFsaWduLWNlbnRlcnt3aWR0aDoxMDAlO2Rpc3BsYXk6ZmxleDthbGlnbi1jb250ZW50OmNlbnRlcn0udGItZ3JpZC1jb2x1bW4udGItZ3JpZC1hbGlnbi1ib3R0b217d2lkdGg6MTAwJTtkaXNwbGF5OmZsZXg7YWxpZ24tY29udGVudDpmbGV4LWVuZH0gLndwLWJsb2NrLXRvb2xzZXQtYmxvY2tzLWdyaWQudGItZ3JpZFtkYXRhLXRvb2xzZXQtYmxvY2tzLWdyaWQ9IjNkYTQ5MjRmMTdiYzdkNDRhZWI5YWI3ZWQ0MjRlYzk2Il0geyBncmlkLXRlbXBsYXRlLWNvbHVtbnM6IG1pbm1heCgwLCAxZnIpO2dyaWQtYXV0by1mbG93OiByb3cgfSAud3AtYmxvY2stdG9vbHNldC1ibG9ja3MtZ3JpZC50Yi1ncmlkW2RhdGEtdG9vbHNldC1ibG9ja3MtZ3JpZD0iM2RhNDkyNGYxN2JjN2Q0NGFlYjlhYjdlZDQyNGVjOTYiXSAgPiAudGItZ3JpZC1jb2x1bW46bnRoLW9mLXR5cGUoMW4rMSkgeyBncmlkLWNvbHVtbjogMSB9IC53cC1ibG9jay10b29sc2V0LWJsb2Nrcy1ncmlkLWNvbHVtbi50Yi1ncmlkLWNvbHVtbltkYXRhLXRvb2xzZXQtYmxvY2tzLWdyaWQtY29sdW1uPSI0NTUwYzU5NGQyNTYxOWQ2NzM4NmFlZmY0YzZhYjU5NSJdIHsgZGlzcGxheTogZmxleDsgfSAudGItYnV0dG9ue2NvbG9yOiNmMWYxZjF9LnRiLWJ1dHRvbi0tbGVmdHt0ZXh0LWFsaWduOmxlZnR9LnRiLWJ1dHRvbi0tY2VudGVye3RleHQtYWxpZ246Y2VudGVyfS50Yi1idXR0b24tLXJpZ2h0e3RleHQtYWxpZ246cmlnaHR9LnRiLWJ1dHRvbl9fbGlua3tjb2xvcjppbmhlcml0O2N1cnNvcjpwb2ludGVyO2Rpc3BsYXk6aW5saW5lLWJsb2NrO2xpbmUtaGVpZ2h0OjEwMCU7dGV4dC1kZWNvcmF0aW9uOm5vbmUgIWltcG9ydGFudDt0ZXh0LWFsaWduOmNlbnRlcjt0cmFuc2l0aW9uOmFsbCAwLjNzIGVhc2V9LnRiLWJ1dHRvbl9fbGluazpob3ZlciwudGItYnV0dG9uX19saW5rOmZvY3VzLC50Yi1idXR0b25fX2xpbms6dmlzaXRlZHtjb2xvcjppbmhlcml0fS50Yi1idXR0b25fX2xpbms6aG92ZXIgLnRiLWJ1dHRvbl9fY29udGVudCwudGItYnV0dG9uX19saW5rOmZvY3VzIC50Yi1idXR0b25fX2NvbnRlbnQsLnRiLWJ1dHRvbl9fbGluazp2aXNpdGVkIC50Yi1idXR0b25fX2NvbnRlbnR7Zm9udC1mYW1pbHk6aW5oZXJpdDtmb250LXN0eWxlOmluaGVyaXQ7Zm9udC13ZWlnaHQ6aW5oZXJpdDtsZXR0ZXItc3BhY2luZzppbmhlcml0O3RleHQtZGVjb3JhdGlvbjppbmhlcml0O3RleHQtc2hhZG93OmluaGVyaXQ7dGV4dC10cmFuc2Zvcm06aW5oZXJpdH0udGItYnV0dG9uX19jb250ZW50e3ZlcnRpY2FsLWFsaWduOm1pZGRsZTt0cmFuc2l0aW9uOmFsbCAwLjNzIGVhc2V9LnRiLWJ1dHRvbl9faWNvbnt0cmFuc2l0aW9uOmFsbCAwLjNzIGVhc2U7ZGlzcGxheTppbmxpbmUtYmxvY2s7dmVydGljYWwtYWxpZ246bWlkZGxlO2ZvbnQtc3R5bGU6bm9ybWFsICFpbXBvcnRhbnR9LnRiLWJ1dHRvbl9faWNvbjo6YmVmb3Jle2NvbnRlbnQ6YXR0cihkYXRhLWZvbnQtY29kZSk7Zm9udC13ZWlnaHQ6bm9ybWFsICFpbXBvcnRhbnR9LnRiLWJ1dHRvbl9fbGlua3tiYWNrZ3JvdW5kLWNvbG9yOiM0NDQ7Ym9yZGVyLXJhZGl1czowLjNlbTtmb250LXNpemU6MS4zZW07bWFyZ2luLWJvdHRvbTowLjc2ZW07cGFkZGluZzowLjU1ZW0gMS41ZW0gMC41NWVtfSBoMi50Yi1oZWFkaW5nW2RhdGEtdG9vbHNldC1ibG9ja3MtaGVhZGluZz0iNmY4MzVjZDQyZTQzZjkxOGRlZTA1ZTkwOTUxYzg3YWMiXSAgeyBtYXJnaW4tYm90dG9tOiAtMyU7IH0gIC53cC1ibG9jay10b29sc2V0LWJsb2Nrcy1ncmlkLWNvbHVtbi50Yi1ncmlkLWNvbHVtbltkYXRhLXRvb2xzZXQtYmxvY2tzLWdyaWQtY29sdW1uPSJiNjMwMGU0YThlMGZhMzA5N2JhMGFjMTkwMmFhZTE4NiJdIHsgZGlzcGxheTogZmxleDsgfSAudGItaW1hZ2Utc2xpZGVyLS1jYXJvdXNlbHtvcGFjaXR5OjA7ZGlyZWN0aW9uOmx0cn0udGItaW1hZ2Utc2xpZGVyIC5nbGlkZXtwb3NpdGlvbjpyZWxhdGl2ZX0udGItaW1hZ2Utc2xpZGVyIC5nbGlkZV9fc2xpZGV7aGVpZ2h0OmF1dG87cG9zaXRpb246cmVsYXRpdmU7bWFyZ2luLWxlZnQ6MH0udGItaW1hZ2Utc2xpZGVyIC5nbGlkZV9fc2xpZGUtLWNsb25le2N1cnNvcjpwb2ludGVyfS50Yi1pbWFnZS1zbGlkZXIgLmdsaWRlX19zbGlkZSBpbWd7d2lkdGg6MTAwJTtmbG9hdDpub25lICFpbXBvcnRhbnR9LnRiLWltYWdlLXNsaWRlciAuZ2xpZGVfX3ZpZXd7d2lkdGg6MTAwJTt0cmFuc2l0aW9uOm9wYWNpdHkgMzUwbXMgZWFzZS1pbi1vdXQ7cG9zaXRpb246cmVsYXRpdmV9LnRiLWltYWdlLXNsaWRlciAuZ2xpZGVfX3ZpZXcgaW1ney1vLW9iamVjdC1maXQ6Y29udGFpbjtvYmplY3QtZml0OmNvbnRhaW47d2lkdGg6MTAwJTtmbG9hdDpub25lICFpbXBvcnRhbnR9LnRiLWltYWdlLXNsaWRlciAuZ2xpZGVfX3ZpZXctLWZhZGUtb3V0e29wYWNpdHk6MH0udGItaW1hZ2Utc2xpZGVyIC5nbGlkZV9fdmlldy0tZmFkZS1pbntvcGFjaXR5OjF9LnRiLWltYWdlLXNsaWRlciAuZ2xpZGVfX2Fycm93e2JvcmRlcjpub25lO3Bvc2l0aW9uOmFic29sdXRlO3otaW5kZXg6MTA7dG9wOjUwJTtkaXNwbGF5OmlubGluZS1mbGV4O2p1c3RpZnktY29udGVudDpjZW50ZXI7YWxpZ24taXRlbXM6Y2VudGVyO3dpZHRoOjQwcHg7aGVpZ2h0OjQwcHg7dGV4dC1hbGlnbjpjZW50ZXI7cGFkZGluZzowO2N1cnNvcjpwb2ludGVyO3RyYW5zZm9ybTp0cmFuc2xhdGVZKC01MCUpO2JvcmRlci1yYWRpdXM6NTBweDt0cmFuc2l0aW9uOmFsbCAwLjJzIGxpbmVhcjtiYWNrZ3JvdW5kOnJnYmEoMjU1LDI1NSwyNTUsMC43KX0udGItaW1hZ2Utc2xpZGVyIC5nbGlkZV9fYXJyb3c6Zm9jdXN7b3V0bGluZTpub25lO2JveC1zaGFkb3c6MCAwIDVweCAjNjY2O2JhY2tncm91bmQ6cmdiYSgyNTUsMjU1LDI1NSwwLjcpO29wYWNpdHk6MX0udGItaW1hZ2Utc2xpZGVyIC5nbGlkZV9fYXJyb3c6aG92ZXJ7YmFja2dyb3VuZDpyZ2JhKDI1NSwyNTUsMjU1LDAuOSl9LnRiLWltYWdlLXNsaWRlciAuZ2xpZGVfX2Fycm93LS1sZWZ0e2xlZnQ6NXB4fS50Yi1pbWFnZS1zbGlkZXIgLmdsaWRlX19hcnJvdy0tbGVmdCBzdmd7bWFyZ2luLWxlZnQ6LTFweH0udGItaW1hZ2Utc2xpZGVyIC5nbGlkZV9fYXJyb3ctLWxlZnQgc3Bhbi50Yi1zbGlkZXItbGVmdC1hcnJvd3tkaXNwbGF5OmlubGluZS1ibG9jazt3aWR0aDoyNXB4O2hlaWdodDoyNXB4O2JhY2tncm91bmQtaW1hZ2U6dXJsKCJkYXRhOmltYWdlL3N2Zyt4bWwsJTNDc3ZnIHhtbG5zPSdodHRwOi8vd3d3LnczLm9yZy8yMDAwL3N2Zycgdmlld0JveD0nMCAwIDEyOSAxMjknIHdpZHRoPScyNScgaGVpZ2h0PScyNSclM0UlM0NnJTNFJTNDcGF0aCBkPSdtNzAsOTMuNWMwLjgsMC44IDEuOCwxLjIgMi45LDEuMiAxLDAgMi4xLTAuNCAyLjktMS4yIDEuNi0xLjYgMS42LTQuMiAwLTUuOGwtMjMuNS0yMy41IDIzLjUtMjMuNWMxLjYtMS42IDEuNi00LjIgMC01LjhzLTQuMi0xLjYtNS44LDBsLTI2LjQsMjYuNGMtMC44LDAuOC0xLjIsMS44LTEuMiwyLjlzMC40LDIuMSAxLjIsMi45bDI2LjQsMjYuNHonIGZpbGw9JyUyMzY2NicvJTNFJTNDL2clM0UlM0Mvc3ZnJTNFIil9LnRiLWltYWdlLXNsaWRlciAuZ2xpZGVfX2Fycm93LS1yaWdodHtyaWdodDo1cHh9LnRiLWltYWdlLXNsaWRlciAuZ2xpZGVfX2Fycm93LS1yaWdodCBzdmd7bWFyZ2luLXJpZ2h0Oi0xcHh9LnRiLWltYWdlLXNsaWRlciAuZ2xpZGVfX2Fycm93LS1yaWdodCBzcGFuLnRiLXNsaWRlci1yaWdodC1hcnJvd3tkaXNwbGF5OmlubGluZS1ibG9jazt3aWR0aDoyNXB4O2hlaWdodDoyNXB4O2JhY2tncm91bmQtaW1hZ2U6dXJsKCJkYXRhOmltYWdlL3N2Zyt4bWwsJTNDc3ZnIHhtbG5zPSdodHRwOi8vd3d3LnczLm9yZy8yMDAwL3N2Zycgdmlld0JveD0nMCAwIDEyOSAxMjknIHdpZHRoPScyNScgaGVpZ2h0PScyNSclM0UlM0NnJTNFJTNDcGF0aCBkPSdtNTEuMSw5My41YzAuOCwwLjggMS44LDEuMiAyLjksMS4yIDEsMCAyLjEtMC40IDIuOS0xLjJsMjYuNC0yNi40YzAuOC0wLjggMS4yLTEuOCAxLjItMi45IDAtMS4xLTAuNC0yLjEtMS4yLTIuOWwtMjYuNC0yNi40Yy0xLjYtMS42LTQuMi0xLjYtNS44LDAtMS42LDEuNi0xLjYsNC4yIDAsNS44bDIzLjUsMjMuNS0yMy41LDIzLjVjLTEuNiwxLjYtMS42LDQuMiAwLDUuOHonIGZpbGw9JyUyMzY2NicvJTNFJTNDL2clM0UlM0Mvc3ZnJTNFIil9LnRiLWltYWdlLXNsaWRlciAuZ2xpZGU6aG92ZXIgLmdsaWRlX19hcnJvdywudGItaW1hZ2Utc2xpZGVyIC5nbGlkZTpmb2N1cyAuZ2xpZGVfX2Fycm93e29wYWNpdHk6MX0udGItaW1hZ2Utc2xpZGVyLS1jcm9wIC5nbGlkZV9fc2xpZGUgaW1ney1vLW9iamVjdC1maXQ6Y292ZXI7b2JqZWN0LWZpdDpjb3ZlcjtoZWlnaHQ6MTAwJSAhaW1wb3J0YW50fS50Yi1pbWFnZS1zbGlkZXIgLmdsaWRlX19zbGlkZXN7bGlzdC1zdHlsZS10eXBlOm5vbmU7cGFkZGluZy1sZWZ0OjA7bWFyZ2luLWxlZnQ6YXV0b30udGItaW1hZ2Utc2xpZGVyX19jYXB0aW9ue3Bvc2l0aW9uOmFic29sdXRlO2JvdHRvbTowO3dpZHRoOjEwMCU7YmFja2dyb3VuZDpyZ2JhKDI1NSwyNTUsMjU1LDAuNik7dGV4dC1hbGlnbjpjZW50ZXI7Y29sb3I6IzMzM30udGItaW1hZ2Utc2xpZGVyX19jYXB0aW9uIDplbXB0eXtiYWNrZ3JvdW5kOnRyYW5zcGFyZW50ICFpbXBvcnRhbnQ7bWFyZ2luOjA7cGFkZGluZzowfS50Yi1pbWFnZS1zbGlkZXJfX2NhcHRpb24gZmlnY2FwdGlvbntwYWRkaW5nOjVweCAycHg7bWFyZ2luLXRvcDo1cHh9IH0g

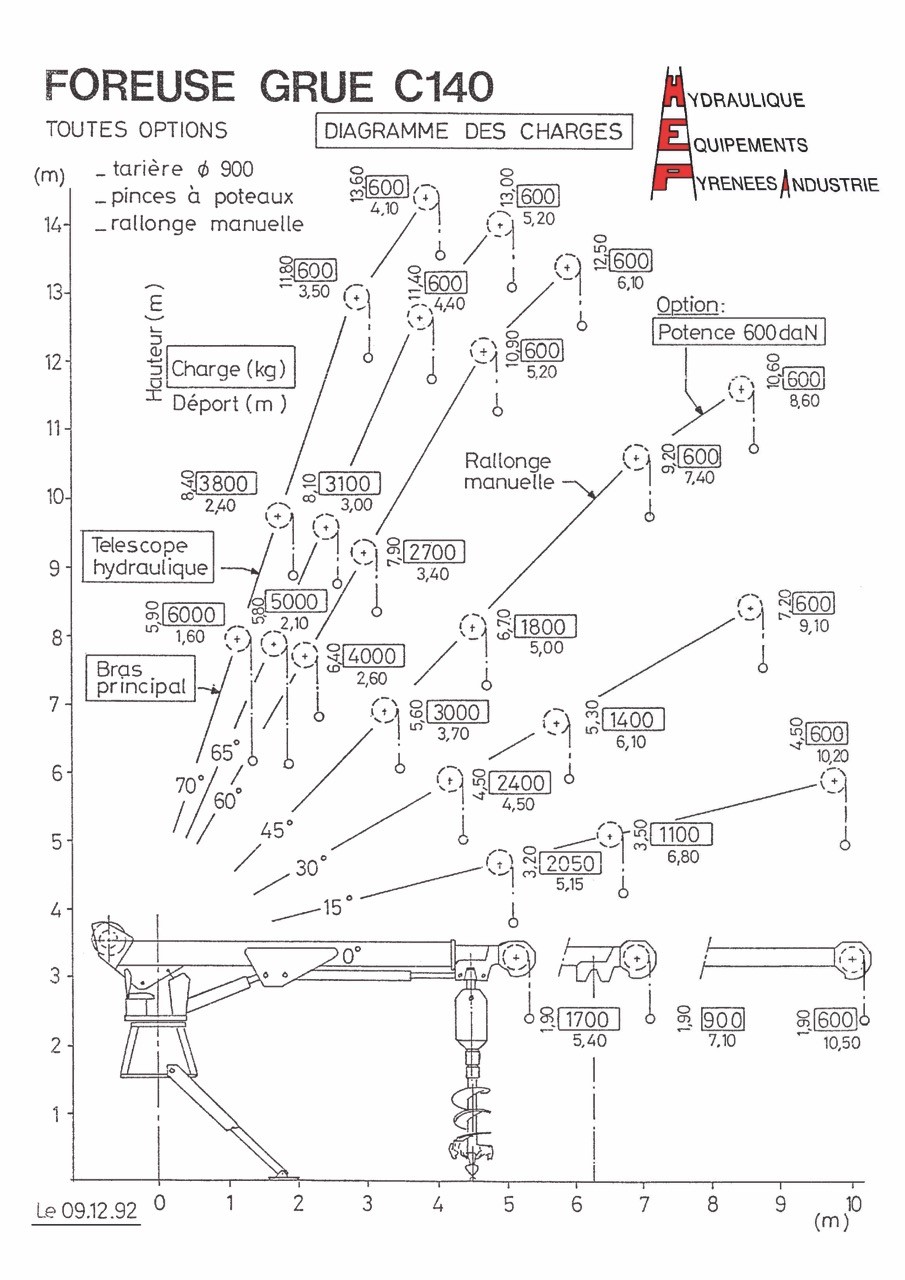

The HEP INDUSTRIE C140 is a digger derrick with a higher load capacity than our TL12 model.

Equipements des foreuses grues C140 ( tarière lève poteaux )

-

- Fixed main boom

- 1-member telescopic beam + 3.40-m manual extension + (optional 1.8-m jib)

- Hydraulic power supply to the boom head by means of telescopic pipes

- Double-acting lift cylinder with 1-cylinder non-return valve

- Lateral control station on turret for improved visibility

- Turret rotation by continuous planetary rotation reducer (hydraulic and electric rotary joints)

- Paire de stabilisateurs en A à l’avant et l’arrière

- Lift winch with planetary reduction, mechanical brake with hydraulic pressure failure

- Hydraulic overload protection

- Electrical capacity limiter

- Moment limiter with pressure tapping on the main arm cylinder

- Safety limit high hook with counterweight

- Lifting cable: diameter: 16 mm; length: 40 m

- Lifting capacity depending on the machine’s 360° angle of rotation

- Hydraulic tank with 220-L air cooler

- A drilling engine with storage along the arm

- Socket for hydraulic tools (140 bar – 20 l/min)

- Pre-equipped with post clamps

- EU compliant

STANDARD BODYBUILD

- Manufacture and flatbed installation

- Non-slip marine treated melamine floor

- Machine support

- Fixed panels on the right and left sides of the flatbed

- Auger/core drill storage space on flatbed

- Pole holders on cab

- Fire extinguisher

- Traffic cone storage

- Storage panels on the back of the cabin

- Pebble crate

- Storage boxes on or under the flatbed: according to the bodywork plan drawn up further to the quotation

- Ladder or access stairs

- Road signs and markings in compliance with the Highway Code

- Painted in the company’s colours

- Delivery and lift commissioning by regulatory control body

In addition, training in the use of the auger post remover C 140 is provided during machine handover. HEP INDUSTRIE is also UTAC qualified, guaranteeing your delivery time and compliance with technical standards.

Options of C140 Piling rig

Tools :

- Core drills from 300 mm to 900 mm in diameter

- Augers from 250 mm to 900 mm in diameter, equipped for hard or soft ground

- Hydraulic tools: grinder, water pump, concrete breaker, vibrating needle, tamper, hydraulic post pruner…

MACHINE OPTIONS

- Remote control

- Swivel post clamp at the end of the boom head and clamp reducer for wooden posts

- 6 T pulley block

- Kit Emergency hand pump

- Emergency electro-pump

CAMBER OPTIONS

- Front and rear towing winches with the characteristics required

- Composite chocks for stabilizer pads

- Removable panels

- PVC tubes for storage of fabric panels

- Right and left manually extendible oversized post holders

- Storage boxes in the desired size

- Reinforced protection cap on top of the cab

- Hydraulic reel (tool socket)

- Oxy-acetylene torch reel

- Compressed air reel

- Oxy-acetylene bottle holder

- Additional pebble crate or sand/gravel bucket

- Water tank

- Electric or manually raised ‘tri-flash’ hazard warning triangle

- Flashing lights (Flashing lights and/or penetrating fog lights)

- Additional work lights

- 3.5T hook or more depending on the pre-equipment of the carrier

- Bespoke bodybuild available on request

- Minimum GVW of the truck-mounted winch in Tonnes: 16 T / 19 T*

- Minimum wheelbase between axles 1 and 2* (Prior validation by our design office required for axle-load verification) : 3.8 m

- A bodywork socket for accelerating, decelerating, stopping and starting the engine from the machine’s control unit..

- Rear impact guard

- Reinforced suspension

- Differential lock

- Echappement in the recommended direction

- Reverse beeper

- Hollow-shaft power take-off (450 Nm /R.1)

- Max. Height Under Hook (m) : 11.8

- Lifting winch force on one strand (daN) : 4000

- Lifting winch force on one strand (daN) : 6000

- Core drills (mm) : 900