CSR

We are convinced that it is essential to progessively adopt sustainable solutions which benefit both our clients and our employees. That is why we decided to progressively commit ourselves to a Corporate Social Responsability (CSR) process. This approach aims to reduce our impact on the Earth while respecting environmental, social and societal values.

If it seems our contribution to society mostly relies on the sustainability of our products and our decreasing energy consumption, we believe our responsability goes further.

When most of our contribution to society is the sustainability of our products and our low-energy consumption, we are certain of the fact that our responsability goes beyond that.

OUR ACTIONS FOR THE ENVIRONMENT

We are certain that one of the most important issues of the years to come is the environment. As a result, the company has reviewed its vision and conduct in order to gradually adopt a sustainable approach.

To start with, we modified our construction site in order to reduce polluting emissions and the energy loss.

A photovoltaic central

We built a photovoltaic central and another one is on the way so, in the future, our company becomes self-sufficient in electricity thanks to the sunlight. This installation, together with numerous individual energy-saving actions, (turning lights on and off at the right time, switching off power strips, starting up equipment at the right time, policy of choosing energy-efficient equipment) has leaded our electricty consumption to decrease by up to 70% several times during the year.

Electric charging stations

Four electric charging stations have been installed since 2018, as some of our company vehicles are hybrid or electric and we want to encourage our employees to turn to more sustainable means of transport.

Sustainable lighting

As part of this drive to make our electricity consumption more sustainable, all our offices and workshops are equipped with LED lamps, and our night-time outdoor lighting schedules have been aligned with those of the commune of Séméac. The town itself is committed to a policy of reducing light pollution, in order to minimize the impact on nature (disruption or even extinction of flora and fauna, restricted access to the starry sky, etc.) and on human activity (lighting is a significant expense, with harmful consequences for human health). So we decided to follow its lead.

Eco-conception

In the meantime, our approach to product development has evolved. Eco-design is now a major preoccupation for our Design Office. Indeed, for our customers, having a machine that is both high-performance and energy-efficient is a real challenge, for economic as well as environmental reasons. The HEP Molly crane drill was created to meet this new demand.

Refurbishment

Last but not least, a significant part of our business is dedicated to the customized refurbishment of your equipment. We believe in giving every machine a second chance, and we are committed to prolonging their lifespan while improving their quality. For example, we carry out complete retrofits of hydraulic machines to create a circular economy and reduce the extraction of raw materials.

COMMITMENT TO DIGITAL SOBRIETY

Because of server systems, all digital activity consumes energy.

So, in order to reduce our digital impact, we have developed a policy of digital sobriety. The emphasis on the longevity of our working tools that we mentioned earlier is reflected in our IT equipment, which is made up entirely of reconditioned computers and devices.

It is important to us that all employees are trained in good practices to minimize their digital impact. Consequently, an IT charter has been signed by all employees to formalize this joint effort towards greater sobriety.

ATTENTION TO SOCIAL ISSUE

Social responsibility is the second fundamental pillar of CSR. That’s why HEP Industrie is keen to develop this dimension within the company.

In-house training

After conducting individual annual and professional interviews (every 2 years) with our employees, we organize targeted skills training for each of them. In this way, each employee participates in at least one training session per year. This is important for the company’s efficiency and profitability, of course, but also, and above all, to ensure that our team is constantly engaged in a stimulating learning process, which is fundamental to well-being in the workplace.

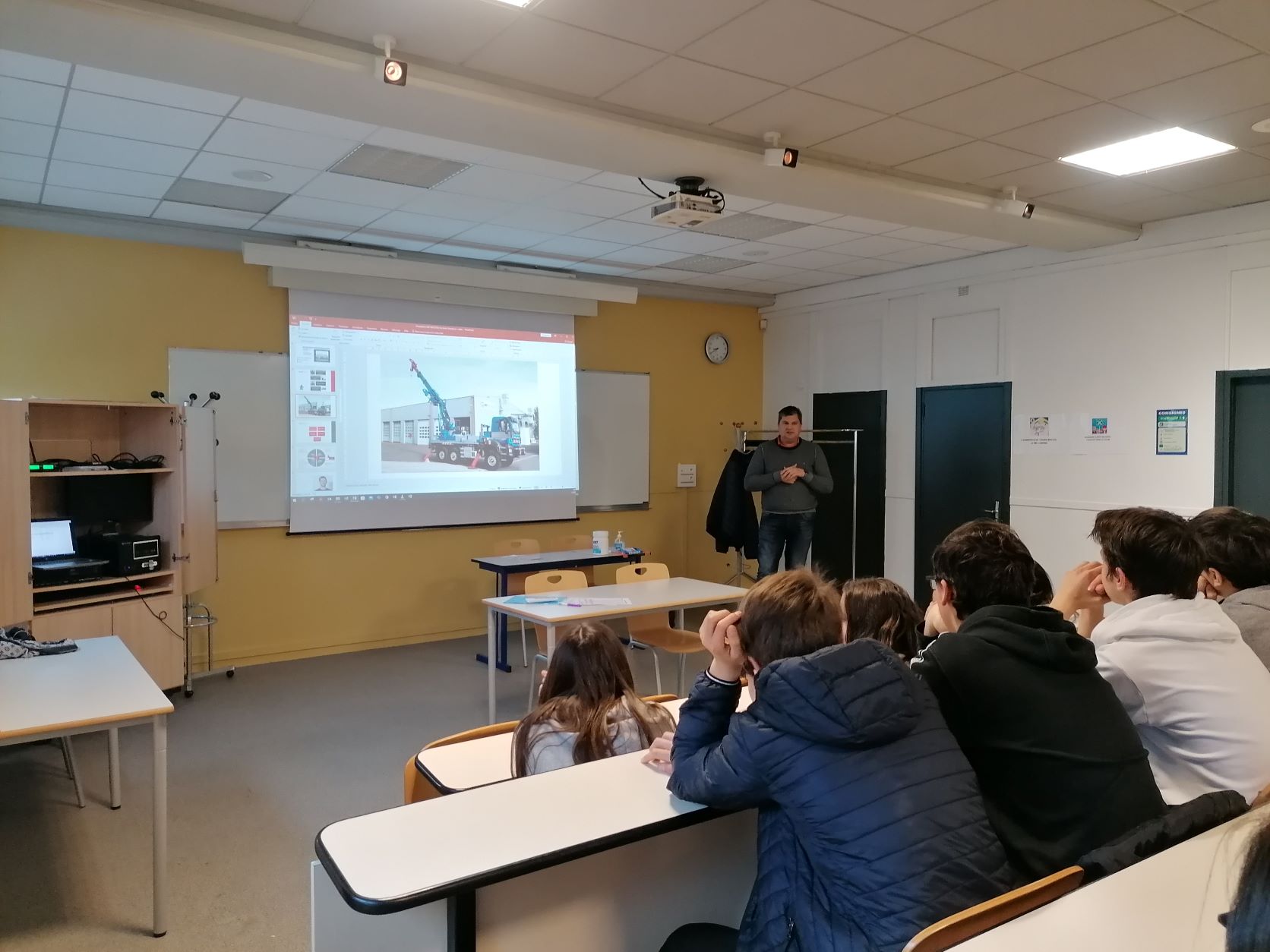

Training of young people

Moreover, we also attach great importance to training young people. This is the reason why, today, we work alongside 6 apprentices and many interns come to boost our business. Indeed, we work closely with schools to give students the opportunity to immerse themselves in the industrial sector and learn by doing. This process gives us the chance to transmit our knowledge and to stay close to younger generation.

The PAQTE program

We signed the PAQTE program, which commits us to hire year 10 interns and apprentices from priority neighbourhoods, as well as taking part in mock interviews and presenting our company’s professions in middle schools and high schools. Guidance is a real issue for all student and we think it is important to make them discover the range of jobs and opportunities available in our sector and, thus, facilitate the projection of young people from all backgrounds into the industrial world, which is generally unknown to them.

Industry Week

For two years now, we’ve been opening our doors to over 50 people during Industry Week. This event gives students and job-seekers the chance to see what the industrial sector is really like. To organize these meetings, we have collaborated with Tarbes IUT, UIMM, Pôle emploi, Mission Locale, Récup Action 65, Atelier Chantier d’Insertion du PLVG, CIBC and Entraide Services.

School of Production

Moreover, we support the building of the future School of Production in Lanne by the Union des Industries et des Métiers de la Métallurgie, in order to train young people in these sectors. One of our employees is Vice-President on the board.

Involvment in the territory

Finally, we are involved in the local economy on a daily basis. Indeed, 70% of our subcontractors are located less than 100km from our production site. We have established relationships with work integration establishments, and work with a number of social enterprises: ESAT in Séméac, Récup’Action Tarbes, APF Entreprise 64 in Sauvagnon, etc…